Custom combination pintle hook, Cheap coupling a pintle hook, forged pintle hook Wholesaler

Pintle hooks are fundamental components in towing systems, providing a reliable connection between trailers and towing vehicles. Among the various types available, combination pintle hooks, forged pintle hooks, and the process of coupling a pintle hook stand out for their durability, versatility, and strength. In this article, we'll delve into the world of pintle hooks, examining these three variations and their applications in towing operations.

Combination Pintle Hook:

Combination pintle hooks are versatile towing components that offer flexibility and reliability in a variety of towing applications. These hooks feature a combination of a pintle hook and a tow ball, providing users with the option to connect trailers equipped with either a pintle hitch or a standard ball hitch. With their dual functionality, combination pintle hooks are ideal for towing a wide range of trailers, including utility trailers, equipment trailers, and agricultural trailers.

One of the key advantages of combination pintle hooks is their convenience and ease of use. By incorporating both a pintle hook and a tow ball into a single unit, these hooks eliminate the need for multiple towing attachments, streamlining the hitching process and reducing setup time. This makes them particularly well-suited for applications where efficiency and versatility are important, such as construction sites, agricultural operations, and industrial settings.

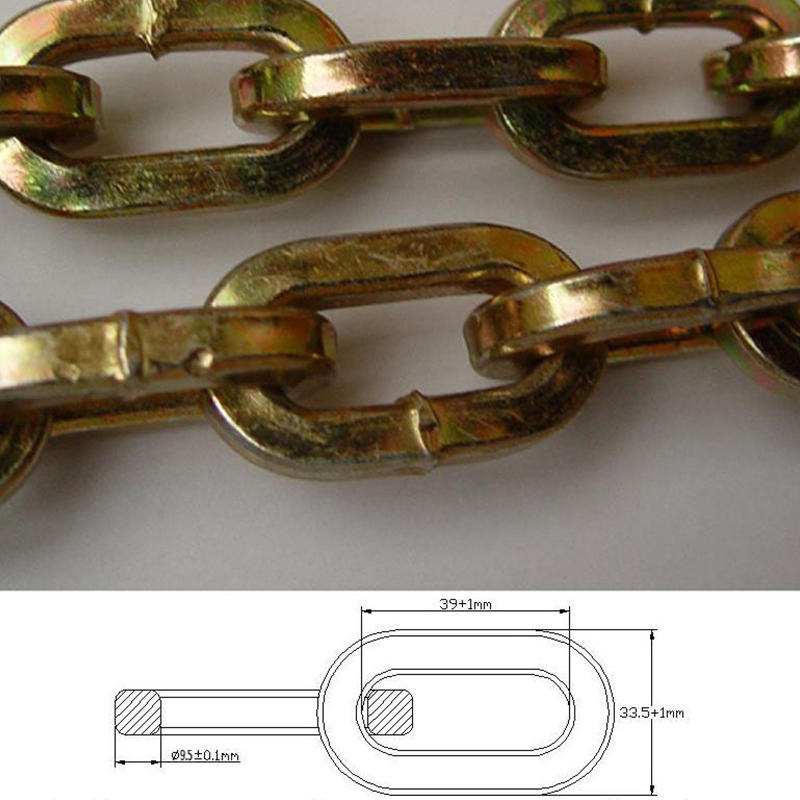

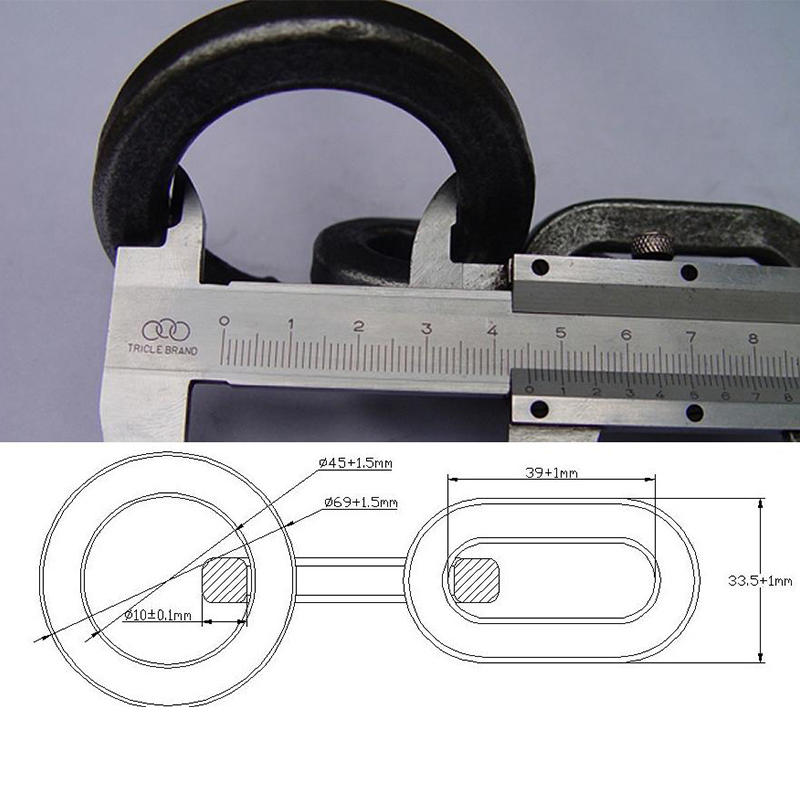

Another benefit of combination pintle hooks is their durability and strength. Constructed from high-quality materials such as forged steel or heavy-duty cast iron, these hooks are designed to withstand heavy loads and rugged towing conditions. Whether towing heavy equipment or hauling construction materials, combination pintle hooks provide a secure and reliable connection that users can trust.

Coupling a Pintle Hook:

Coupling a pintle hook involves the process of attaching the hook to a trailer's pintle hitch, creating a secure connection between the trailer and the towing vehicle. This process requires careful alignment and positioning to ensure a proper fit and prevent accidents or damage during towing operations. Coupling a pintle hook involves several steps, including:

1. Aligning the pintle hook: Position the pintle hook so that it aligns with the pintle hitch on the trailer. Ensure that the hook is centered and level to prevent misalignment or uneven weight distribution.

2. Engaging the latch mechanism: Once the hook is properly aligned, engage the latch mechanism to secure the hook in place. This may involve pulling a lever or rotating a locking mechanism to lock the hook onto the pintle hitch.

3. Securing safety chains: After coupling the pintle hook, attach safety chains from the trailer to the towing vehicle's hitch. These chains provide an additional layer of security in case the pintle hook becomes detached during towing.

Forged Pintle Hook:

Forged pintle hooks are heavy-duty towing components known for their strength, durability, and reliability in demanding towing applications. These hooks are manufactured using a forging process that involves shaping heated metal under high pressure, resulting in a finished product that is exceptionally strong and resilient. With their robust construction and rugged design, forged pintle hooks are ideal for towing heavy loads and navigating rough terrain.

One of the key advantages of forged pintle hooks is their strength and durability. Unlike cast pintle hooks, which are made by pouring molten metal into a mold, forged hooks are formed from a single piece of metal that is shaped and compressed under intense pressure. This process creates a hook that is free from defects and weaknesses, ensuring reliability and safety during towing operations.

Another benefit of forged pintle hooks is their resistance to wear and corrosion. The forging process produces a dense and uniform grain structure in the metal, making it highly resistant to abrasion, impact, and environmental damage. This makes forged pintle hooks ideal for use in harsh conditions, such as off-road towing or marine applications, where exposure to moisture, salt, and debris can cause premature wear and deterioration.

Conclusion:

In conclusion, combination pintle hooks, coupling a pintle hook, and forged pintle hooks are important components in towing systems, providing strength, durability, and reliability in a variety of applications. Whether towing heavy equipment on a construction site or hauling agricultural products on a farm, these hooks offer the versatility and performance needed to get the job done safely and efficiently. By understanding the characteristics and applications of each type of pintle hook, users can select the right tool for their towing needs and ensure a secure and reliable connection between their trailer and towing vehicle.

English

English 中文简体

中文简体