Features and types of chain drive

Chain drive is composed of a sprocket mounted on a parallel shaft and a ring chain across the two sprockets. The chain is used as the middle flexible part that the movement and power are transmitted by the meshing of the chain and the sprocket teeth.

Chain drive structure is simple, durable and easy to maintain which is used in the center distance larger occasions.

Chain drive can maintain accurate average transmission ratio compared with the belt drive. No elastic sliding and slipping; The tensioning force is smaller than belt drive; It can work under harsh environmental conditions such as high temperature and oil pollution.

Chain drive requires lower precision in manufacturing and installation comapred with gear drive which is Low cost and can complete long-distance transmission. But the instantaneous speed is not uniform and the instantaneous transmission ratio is unstable. There is a certain impact and noise in the transmission.

Chain drive structure is simple, durable and easy to maintain which is used in the center distance larger occasions.

Chain drive can maintain accurate average transmission ratio compared with the belt drive. No elastic sliding and slipping; The tensioning force is smaller than belt drive; It can work under harsh environmental conditions such as high temperature and oil pollution.

Chain drive requires lower precision in manufacturing and installation comapred with gear drive which is Low cost and can complete long-distance transmission. But the instantaneous speed is not uniform and the instantaneous transmission ratio is unstable. There is a certain impact and noise in the transmission.

The transmission ratio of chain drive i≤8; Center distance a≤5~6m; Transmission power P≤100kW; Circumferential speed v≤15m/s; Transmission power η=0.92~0.96.

Chain drive is widely used in mining machinery, agricultural machinery, petroleum machinery, machine tools and motorcycles.

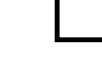

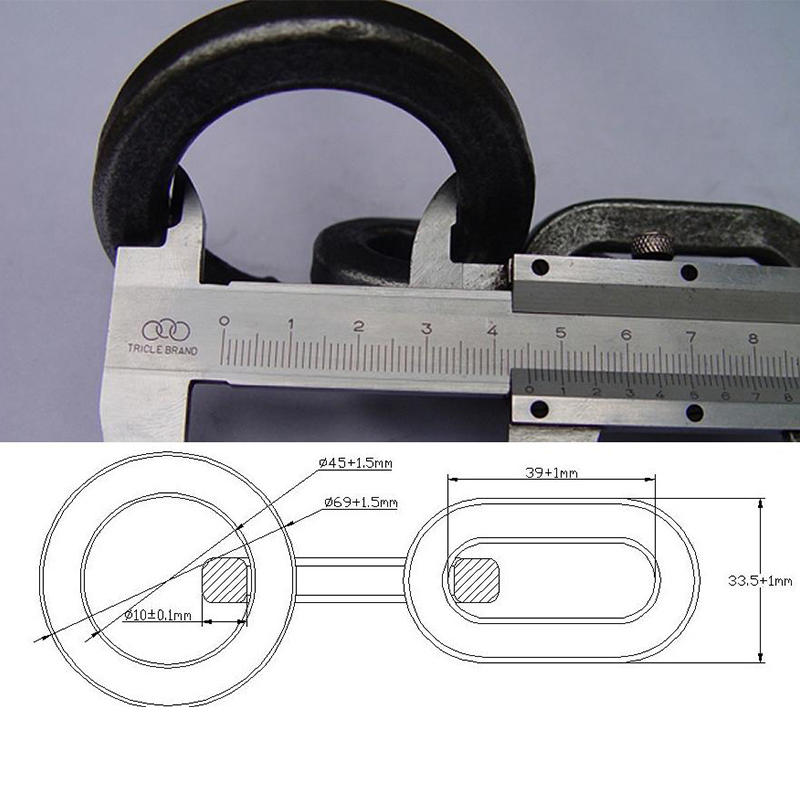

According to the different structure of the chain, the chain has two kinds to transmit the power which is the roller chain and toothed chain. The structure of the toothed chain is messy and the price is high, so its application is not as extensive as the roller chain.

Failure mode of chain drive

1. Fatigue damage of chain plate due to the role of variable stress, through a certain number of cycles, the chain plate will produce fatigue damage, under normal smooth conditions, fatigue strength is the main factor limiting the bearing capacity of chain drive.

2. When the chain link engages with the sprocket, there will be an impact between the roller and the sprocket. At high speed, the impact load is large, the sleeve and the roller surface have impact fatigue damage.

3. When the smooth is poor or the speed is too high, the working surface of the pin and the sleeve conflicts and heating is large, and the two surfaces are adhesive and wear, and the adhesive is generated when the severe.

4. In the process of operation, the working surface of the pin and sleeve will be worn due to relative sliding, resulting in the extension of the chain link, which is easy to cause skip teeth and chain removal.

4. In the process of operation, the working surface of the pin and sleeve will be worn due to relative sliding, resulting in the extension of the chain link, which is easy to cause skip teeth and chain removal.

5. At low speed (v<6m/s) heavy loads or instantaneous severe overload, the chain may be pulled.

English

English 中文简体

中文简体