Attention to maintenance of hoist chain and chain ring hook

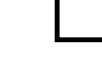

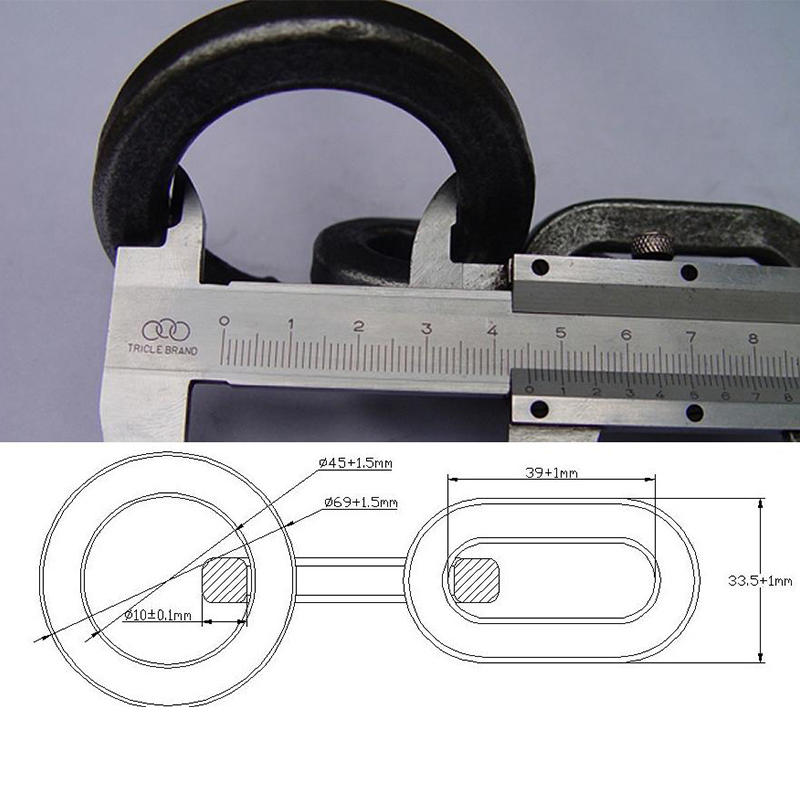

Lifter chains and chain hooks are used in engineering, manufacturing, production lines and special environments. Among the similar products of pet chains, special chains are classified into chain product series according to the basic structure of the chain, i.e., the shape of the components, the parts and parts that are engaged with the chain, and the ratio of the dimensions between the parts. Most of the chains are composed of chain plates, chain pins, bushings and other parts. According to the different needs of the hoist chain, different changes are made, some of them put scrapers on the chain plate, some put guide bearings on the chain plate, and some put rollers on the chain plate, etc. These are all modifications to be applied in different applications. The driving power of the elevator is small, and it adopts inflow feeding, induced discharge, and dense arrangement of large-capacity hopper. There is almost no return and digging phenomenon when the material is lifted, so the invalid power is less. The advanced design principle and processing method of elevator chain ensure the reliability of the whole machine operation, high lifting height and smooth operation of the elevator, so it can reach a high lifting height. As the price of chain steel drops again and again, thus the quality of chain steel gradually declines. Now the chain steel used by the production enterprises is of mixed sources, and the quality of steel is mixed with fish and pearl, which causes the corrosion of the hoist chain. The quality of anti-rust lubricant and cleaning kerosene used in the production is not up to the requirements of the technical regulations is also one of the reasons. The hoist chain maintenance specification is the strict control of chain use by the mine operator. If the chain is worn, both sides of the chain must be replaced at the same time so that the chain pairing can be maintained Check the damaged chain, scraper and sprocket, and replace them if necessary. If too tight it will increase the demand power and chain wear, implement chain management procedures, ensure that all operations are trained and best practices are achieved under the guidance of the conveyor manufacturer, follow maintenance procedures and keep records. Special chains, pet chains

English

English 中文简体

中文简体