Sale OEM Hexagonal Link Security Alloy Steel Chain Manufacturer

In recent years, technological advancements have revolutionized the manufacturing processes of Sale Hexagonal Link Chains, elevating their performance and applicability across various industries. This article explores the cutting-edge techniques and innovations that have reshaped the production of hexagonal link chains, emphasizing their benefits, applications, and future prospects.

The traditional manufacturing of hexagonal link chains involved conventional methods such as casting and forging, which provided basic structural integrity but often lacked precision and efficiency. However, with the advent of modern technologies, including computer-aided design (CAD), computer numerical control (CNC) machining, and additive manufacturing (3D printing), the production landscape has undergone significant transformation.

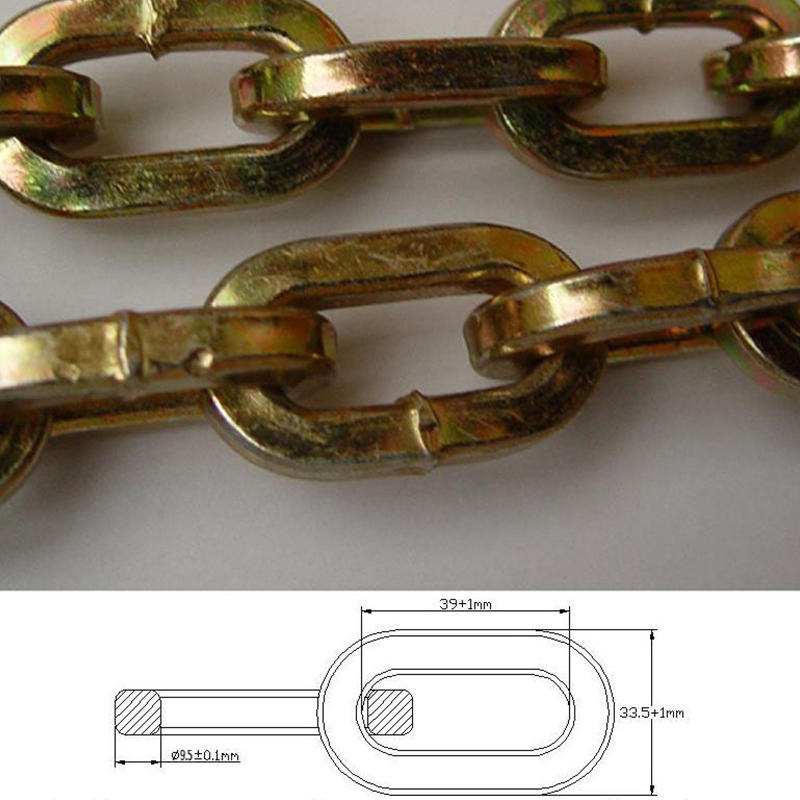

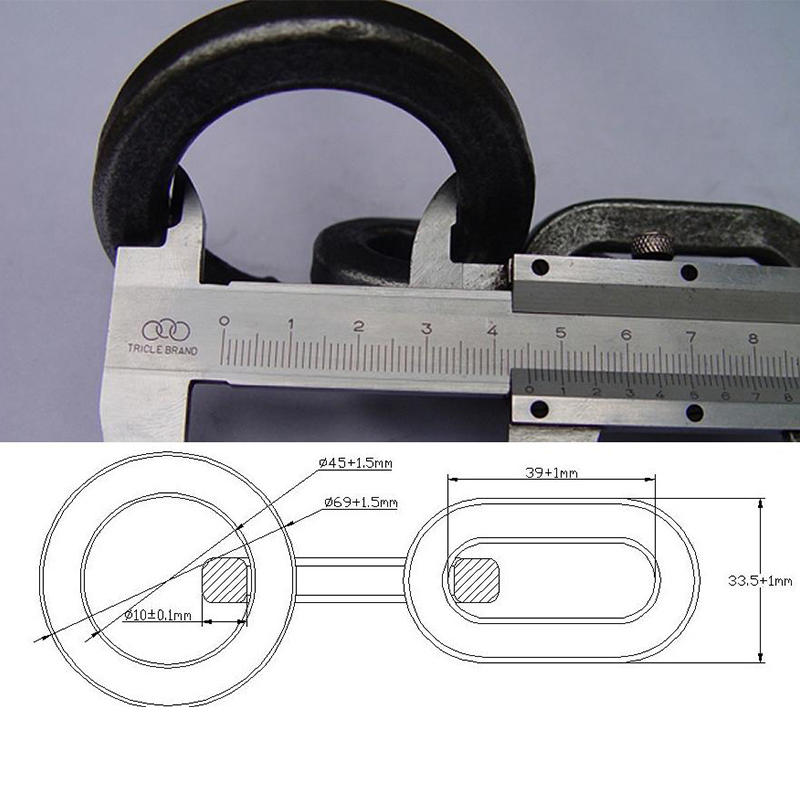

CAD software enables engineers to design intricate geometries and optimize material distribution within hexagonal link chains, enhancing their strength-to-weight ratio and overall performance. CNC machining ensures precise fabrication of chain components, allowing for tight tolerances and consistency in quality across production batches. Additionally, additive manufacturing techniques have enabled the creation of complex geometries and customized designs, catering to specific industry requirements with unparalleled flexibility.

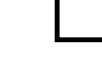

The choice of materials plays a crucial role in the performance and durability of hexagonal link chains. Advanced metallurgical techniques have expanded the range of materials available for manufacturing, offering options that balance strength, corrosion resistance, and weight. High-strength alloys, stainless steels, and specialty materials are now commonplace in the production of OEM Hexagonal Security Chains, each selected based on the application's requirements for load capacity, environmental conditions, and operational lifespan.

Furthermore, advancements in surface treatment technologies, such as coatings and platings, enhance the corrosion resistance and wear resistance of hexagonal link chains, extending their service life in demanding environments. These innovations not only improve the functional characteristics of chains but also contribute to reducing maintenance costs and downtime for users.

As the demand for reliable and high-performance hexagonal link chains grows across industries, stringent quality control measures have become integral to manufacturing processes. Quality management systems, adherence to international standards (e.g., ISO 9001), and rigorous testing protocols ensure that each chain meets specified performance criteria and regulatory requirements.

Alloy Steel Chain Manufacturers find widespread applications in industries where robustness, reliability, and precision are paramount. In automotive manufacturing, these chains are used for conveyor systems and assembly line equipment, facilitating seamless production processes and reducing downtime. The aerospace sector benefits from their lightweight yet durable construction, supporting critical applications in aircraft components and aerospace structures.

Moreover, hexagonal link chains play a pivotal role in heavy machinery, mining, and construction equipment, where they withstand heavy loads, shock forces, and abrasive conditions. Their versatility extends to marine applications, where they are employed in mooring systems, ship anchoring, and offshore rigging, demonstrating resilience against saltwater corrosion and environmental stressors.

Looking ahead, ongoing research and development in manufacturing technologies promise further advancements in hexagonal link chain design and production. Emerging trends include the integration of smart sensors and IoT (Internet of Things) capabilities into chain systems, enabling real-time monitoring of performance metrics such as load distribution, temperature, and wear.

Furthermore, sustainable manufacturing practices, such as recycling and circular economy principles, are gaining traction in the chain manufacturing industry. Efforts to reduce environmental impact and optimize resource utilization are driving innovation in materials sourcing, production efficiency, and end-of-life recycling processes.

n conclusion, technological advances in manufacturing have positioned hexagonal link chains as indispensable components in modern industrial applications. From enhanced design capabilities to improved materials and quality control standards, these chains embody innovation and reliability across diverse sectors. As industries continue to evolve and demand higher standards of performance, the evolution of manufacturing techniques and materials will play a pivotal role in shaping the future of hexagonal link chains, ensuring their continued relevance and effectiveness in a rapidly changing global economy.

English

English 中文简体

中文简体