China OEM Hexagonal Welded Link Chain Steel Maker

In the realm of engineering and design, innovation is the key to progress. One such innovation that has captured the attention of industry professionals is the hexagonal link chain. This article delves into the potential of China Hexagonal Link Chains and how they are revolutionizing the design landscape.

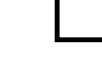

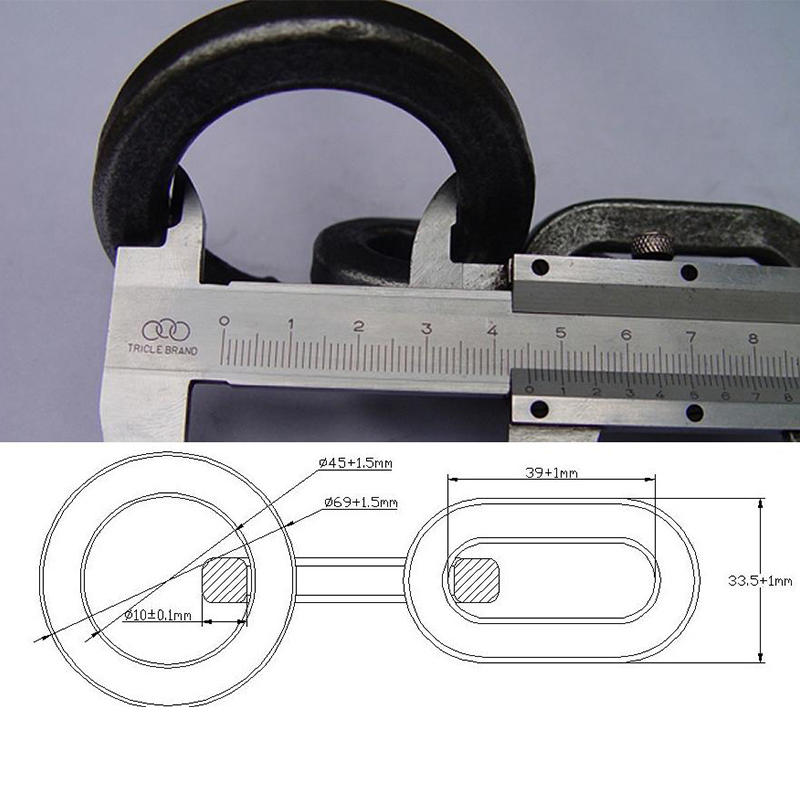

Hexagonal link chains, with their distinctive hexagonal cross-section, offer a range of benefits that traditional round link chains cannot match. The hexagonal design provides greater surface area contact, which translates to increased strength and reduced wear. This is particularly beneficial in high-load applications where reliability is paramount.

The hexagonal link chain's structural integrity is unmatched. The even distribution of forces across the hexagonal links ensures that the chain maintains its shape and strength under stress. This is a critical feature in industries such as construction, where the chain must withstand heavy loads without deformation.

Durability is another hallmark of hexagonal link chains. The hexagonal shape allows for better heat dissipation and resistance to environmental factors, making these chains ideal for use in harsh conditions. This enhanced durability extends the service life of the chain, reducing the need for frequent replacements and maintenance.

The versatility of hexagonal link chains is evident in their wide range of applications. From heavy lifting in the maritime industry to precision engineering in the automotive sector, OEM Welded Link Chains are proving their worth. Their adaptability to various load types and directions makes them a preferred choice for complex rigging systems.

Safety is a critical concern in any industry, and hexagonal link chains contribute significantly to this aspect. The reduced risk of deformation under load means that the chain is less likely to fail unexpectedly, providing a safer working environment for operators and machinery.

The design potential of hexagonal link chains is vast. Engineers and designers are exploring new ways to integrate these chains into innovative systems, pushing the boundaries of what is possible. The hexagonal link chain's unique geometry allows for creative solutions that were previously unattainable.

Let's examine a few case studies that highlight the impact of hexagonal link chains in various industries. In the maritime industry, hexagonal link chains have become the standard for rigging due to their high tensile strength and resistance to corrosion from saltwater. The automotive industry has embraced hexagonal link chains for their suspension systems, leveraging their durability and precision to enhance vehicle performance and safety.

In heavy machinery, Chain Link Steel Makers are used for their robustness and ability to handle the rigors of continuous operation under heavy loads. The aerospace industry utilizes hexagonal link chains for their lightweight yet strong properties, which are crucial for components that must withstand severe conditions.

As we look to the future, the potential of hexagonal link chains continues to expand. With ongoing research and development, we can expect to see even more innovative uses for these chains, further unlocking their potential in design and engineering.

The hexagonal link chain is more than just a link in the chain of progress; it is a catalyst for innovation. By understanding and harnessing the unique properties of hexagonal link chains, designers and engineers can create safer, more efficient, and more durable systems. As the demand for these chains grows, so too will the opportunities for those who are at the forefront of this technological advancement.

English

English 中文简体

中文简体