China Sale Thick Iron Security Chain Factory

The iron chain industry, a cornerstone of heavy-duty applications and construction, has been witnessing a technological revolution. iron chain factories, once bastions of traditional manufacturing methods, are now embracing innovative technologies to enhance efficiency, safety, and sustainability. As an expert in the field, I will explore the transformative impact of these technologies on iron chain factory production.

The integration of automation and robotics in the iron chain factory has been a game-changer. Automated systems can perform repetitive tasks with precision, reducing human error and increasing production speed. Robots can handle high-temperature processes, such as forging and welding, which were previously hazardous for human workers. This not only improves safety but also allows for more complex and intricate chain designs to be produced.

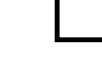

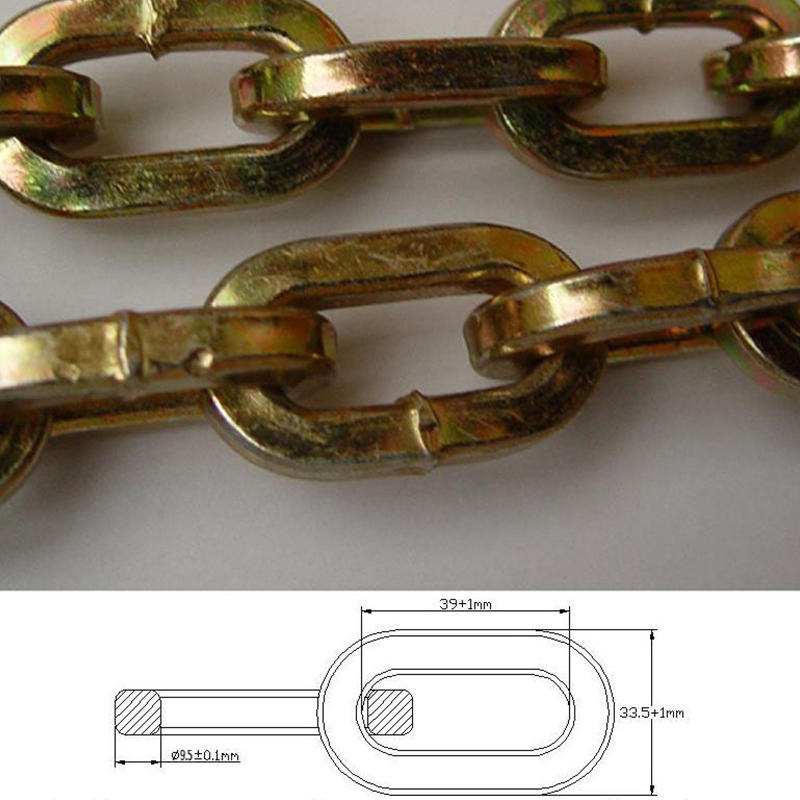

The application of advanced material science has led to the development of stronger, lighter, and more durable iron chains. By understanding the properties of different alloys and their combinations, China Thick Iron Chain can produce chains that are better suited for specific applications, such as marine environments or heavy lifting. This has also opened up new markets for iron chains, such as the aerospace and automotive industries.

Digital twins are virtual replicas of physical systems or processes. In the context of iron chain factories, digital twins can simulate the production process, allowing manufacturers to optimize workflows, reduce waste, and identify potential issues before they occur. This technology enables iron chain factory to make data-driven decisions, resulting in more efficient production and higher-quality output.

The IoT has connected various components of iron chain factory production, from raw material storage to product dispatch. Sensors and connected devices provide real-time data on machine performance, allowing for predictive maintenance and reducing downtime. This interconnectedness also facilitates better inventory management and supply chain optimization.

Additive manufacturing, or 3D printing, is another technology that is transforming iron chain factory production. While traditional manufacturing methods require cutting and shaping materials, 3D printing builds objects layer by layer. This can result in significant material savings and the ability to create complex chain designs that would be difficult or impossible to produce using conventional methods.

Augmented reality is enhancing the training and maintenance processes in iron chain factories. AR can provide workers with real-time, interactive information about machinery and processes, improving safety and efficiency. It can also assist in the assembly and repair of complex chain systems, reducing the need for extensive manuals and training.

With a focus on sustainability, many iron chain factories are adopting energy-efficient technologies. Solar panels, wind turbines, and energy recovery systems are being integrated into factory operations to reduce the carbon footprint and energy costs. This not only benefits the environment but also contributes to the long-term financial health of the iron chain factory.

Advanced quality control technologies, such as computer-aided inspection (CAI) and machine vision systems, are ensuring that iron chains meet higher quality standards. These systems can detect minute defects and irregularities that may be missed by the human eye, resulting in a more consistent and reliable product.

Blockchain technology is being utilized to create transparent and secure supply chains in the iron chain industry. By recording every step of the production and distribution process on a decentralized ledger, Sale Thick Security Chain can ensure the authenticity of its products and trace their origins, enhancing consumer trust and brand reputation.

The iron chain factory is also adopting environmentally friendly practices, such as recycling waste materials and reducing emissions. This not only aligns with global sustainability goals but also helps factories meet regulatory requirements and reduce their environmental impact.

The iron chain industry is at the forefront of a technological renaissance. The iron chain factory that embrace these innovations are not only improving their production capabilities but also contributing to a more sustainable and efficient future. As these technologies continue to evolve, the possibilities for the iron chain industry are boundless, promising a new era of growth and innovation.

English

English 中文简体

中文简体