Wholesale Custom Iron Loop Safety Lock Chain Factory

The iron chain industry is a cornerstone of various sectors, from construction to maritime and automotive applications. Ensuring the durability, strength, and reliability of iron chains is paramount. This article delves into the quality control processes employed in an iron chain factory, highlighting the importance of stringent checks and balances to maintain product integrity and customer satisfaction.

Quality control is a critical component of any manufacturing process, and an iron chain factory is no exception. The term "iron chain factory" encompasses a wide range of facilities that produce chains for different applications. Implementing robust quality control measures ensures that the product meets industry standards and customer expectations.

The initial step in the quality control process in an iron chain factory is the inspection of raw materials. Sourcing high-quality iron is essential for producing durable and reliable chains. Factories must ensure that the iron used is free from impurities and meets the required specifications.

Once the raw materials have been approved, the manufacturing process begins. Wholesale Loop Chain Lock employs various techniques, such as forging, welding, and casting, to produce chains. Continuous monitoring of these processes is crucial to identify any deviations from the established quality standards.

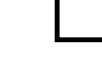

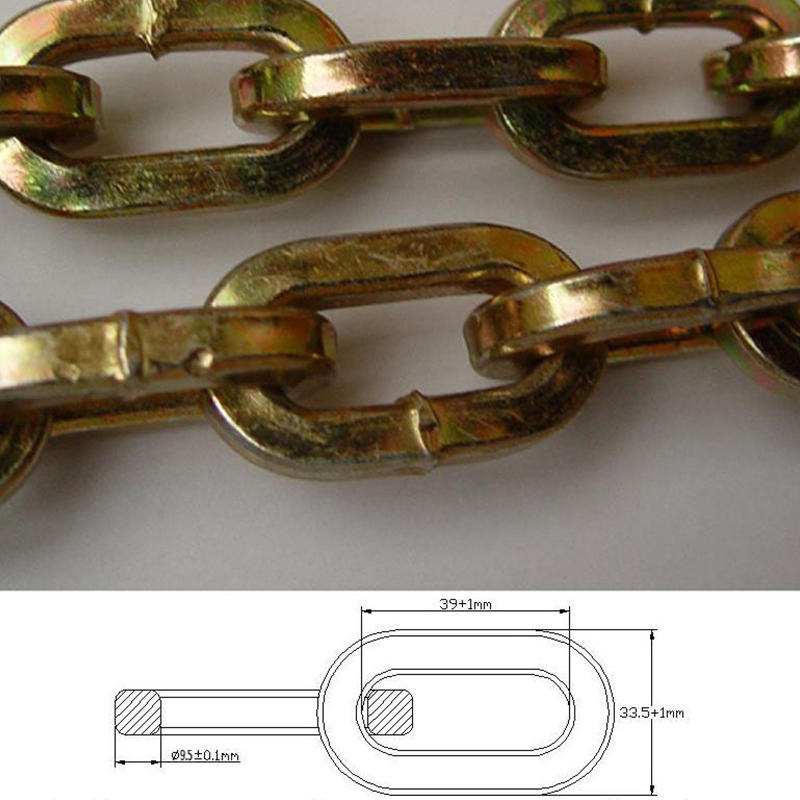

During the manufacturing process, in-process quality checks are conducted to ensure that each stage is completed to the standards. This may involve measuring the dimensions of the chain links, testing the strength of welds, and ensuring that the chain's overall structure is consistent.

After the iron chain has been manufactured, a thorough post-production inspection is carried out. This step is vital in identifying any defects that may have occurred during the production process. Custom Safety Lock Chains must have a detailed inspection protocol in place to ensure that no faulty products leave the facility.

Strength and durability are key characteristics of iron chains. Factories conduct rigorous testing to ensure that their products can withstand the forces they will be subjected to in their intended applications. This may involve tensile tests, fatigue tests, and other forms of stress testing.

Investing in employee training and development is a crucial aspect of quality control in iron chain factories. Well-trained staff are better equipped to identify and rectify issues during the manufacturing process, contributing to the overall quality of the product.

Incorporating advanced technology into the quality control process can significantly improve the efficiency and effectiveness of checks. Iron chain factory may use automated inspection systems, computer-aided design (CAD) software, and other technological tools to enhance their quality control processes.

A commitment to continuous improvement is essential for iron chain factory to stay competitive and meet the evolving needs of their customers. Regularly reviewing and refining quality control processes ensures that the factory remains at the forefront of the industry.

Listening to customer feedback is a valuable source of information for the iron chain factory. Understanding the needs and expectations of customers can help factories identify areas for improvement and ensure that their products continue to meet market demands.

Maintaining accurate documentation and records of the quality control processes is crucial for the iron chain factory. This information can be used for internal audits and regulatory compliance, and to demonstrate the factory's commitment to quality.

Effective management of suppliers is a key aspect of quality control in iron chain factories. Ensuring that suppliers meet the factory's quality standards for raw materials and components contributes to the overall quality of the product.

iron chain factory must also consider the environmental impact of their operations. Implementing eco-friendly practices and reducing waste can contribute to the overall quality of the factory's products and operations.

Collaborating with other iron chain factories and industry stakeholders can result in the sharing of practices and the development of new quality control techniques. This collaboration can help to raise the bar for the entire industry.

Quality control processes in iron chain factory is multifaceted and require a combination of rigorous inspection, testing, employee training, and the use of advanced technology. By maintaining a strong focus on quality, iron chain factories can produce reliable and durable products that meet the needs of their customers and contribute to the success of various industries. The commitment to quality control is not just a matter of compliance; it is a testament to the factory's dedication to excellence and customer satisfaction.

English

English 中文简体

中文简体