Reasons for using lubricants for galvanized iron chains

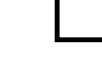

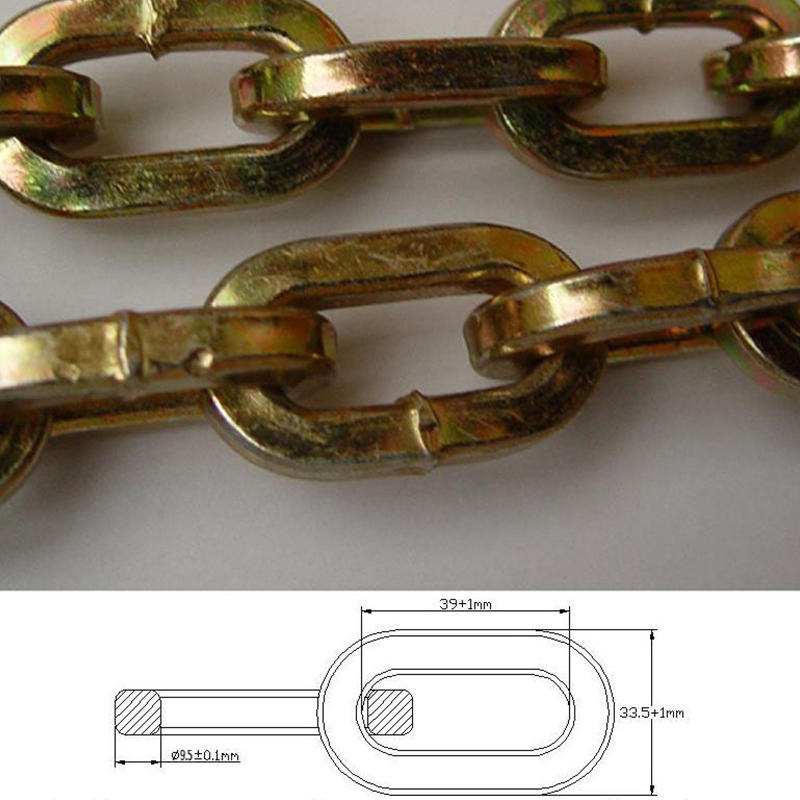

We will use lubricant in the process of daily maintenance, and also galvanized iron chain must be added before the factory to prevent rust lubrication supplies, chain manufacturers will add thickening agent in the lubricant, in order to prevent the loss of dripping oil in the hauling process, so what are the benefits of using lubricant to the bottom of the lock chain? The following is a brief introduction by the editor: whether it is a guardrail chain or galvanized iron chain they are composed of a small chain ring, so the small chain ring will be between by the chain often friction with each other, and over time there will be wear and tear, and in order to reduce the friction between the galvanized iron chain, reduce the friction resistance all the substances can be used as the chain lubricant. Lubricant includes lubricant, solid lubricant, grease, etc. When choosing the lubricant for galvanized iron chain, it is necessary to consider the form of lubrication, chain specification, ambient temperature and other factors, because these factors will affect the performance of the lubricant. Generally, we use chemically stable and high quality mineral oil, and the lubricant with pure composition, no oxidation and no impurities is the best. Various used oils or greases may contain tiny particles and corrosive components, which may cause the failure of galvanized iron chain such as dead joints, so it is necessary to consider the situation of the chain itself when using it. Chains, iron chains

English

English 中文简体

中文简体